Raw Materials

After engineering is confirmed, raw materials will be ordered against the Advance Bill of Material (ABOM),

or the final bill of material (BOM). The main difference in these lists is that the connection design quantities

and the cutting lengths for long products are unknown at the ABOM stage of engineering, but it would save valuable

time to order the materials anyway.

Raw steel is ordered for a specific international grade, application, and

service temperature. Upon receiving, all plates and long material is inspected for delivery quality such as damage,

deformation, dimensional tolerance, and surface oxidation or pitting. To ensure that Material Traceability can be

maintained, no material can be accepted without the Mill Test Report / Certificate (MTR/MTC). The Certificate (MTR/MTC)

identifies the manufacturing mill, steel grade, steel profile, dimensions, heat number, (*plate number), chemical

composition, physical properties, and impact test results.

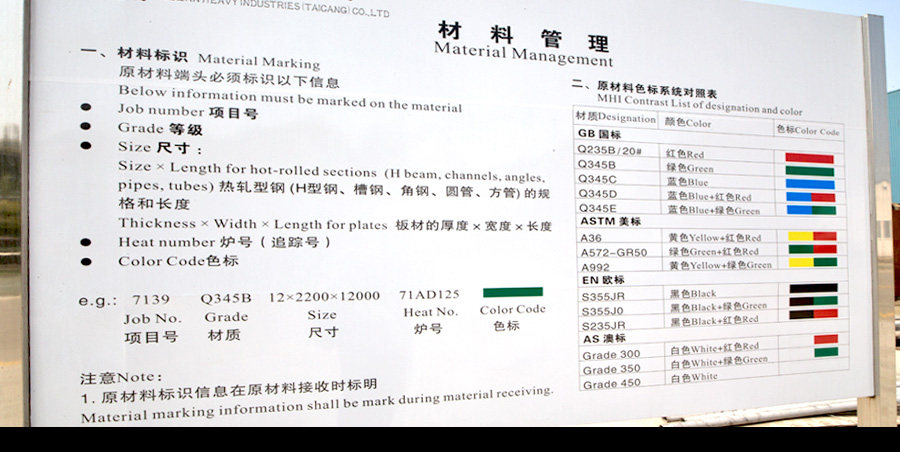

After receiving, steel is classified and color-coded

according to the project number, profile, dimension, and grade. The heat number is transferred to the steel and enters

MDHI’s database. Any non-conforming materials will be tagged and/or marked as non-conforming and segregated from conforming

materials until the materials can be made to conform, or are replaced.

Welding Consumables

As with raw materials, there are procedures for handling welding consumables. MDHI welding engineer approves

the brand and types of consumables to procure according to the welding specification WPS/WPQR. Welding consumables

are stored in a controlled distribution center and segregated according to brand, type, AWS class, and size. The batch

number of the materials allows for traceability.

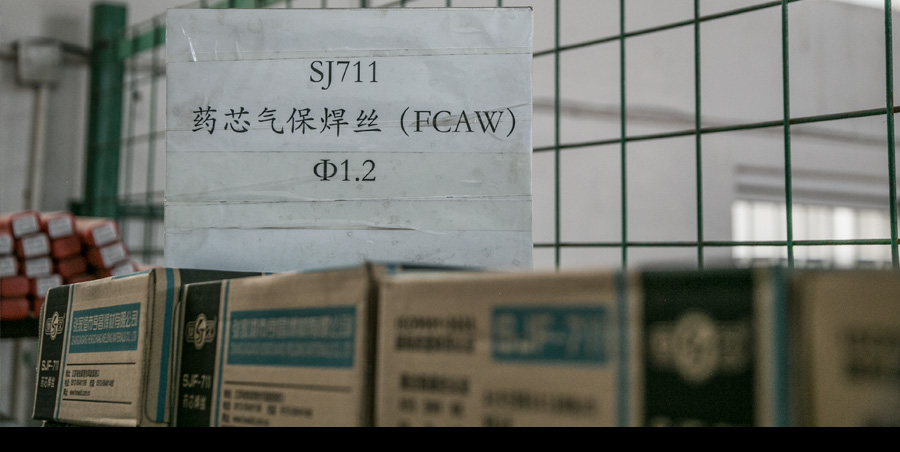

The welding consumable storeroom must be dry and environmentally

controlled, and can only be used for storing welding consumables. FCAW, GMAW, GTAW, SAW, SMAW electrodes, and SAW flux

are the principle items stored. All products must be maintained in the original packaging and stacked on pallets until

requisitioned for use by the be shop welding foreman, or welding team leader.

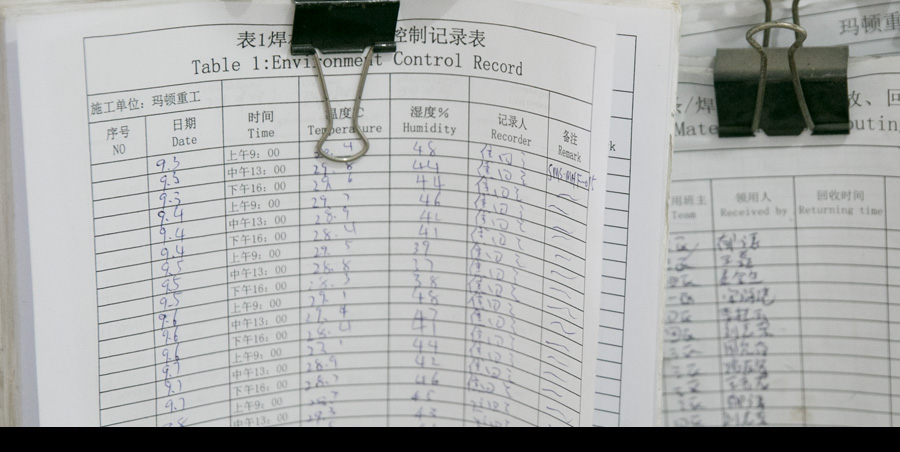

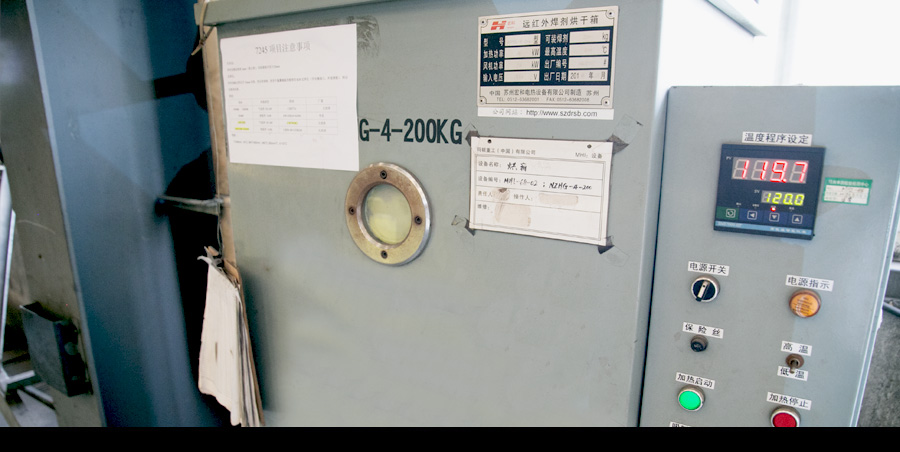

The consumable storage temperature is

kept between 5-25° C. If the temperate is higher, then the humidity must be reduced accordingly. Daily logs are kept of

temperature and humidity taken by using a thermometer and hygrometer, and baking ovens are used to condition SMAW electrodes,

though not often used.

In the workshop, SAW Flux shall is pre-treated in a heated flux holding oven according to the

Welding Engineer's instructions and the flux shall be transferred to SAW machine hoppers. At the end of each shift any

unused flux shall be removed from the SAW hoppers and returned to the heated flux holding oven.